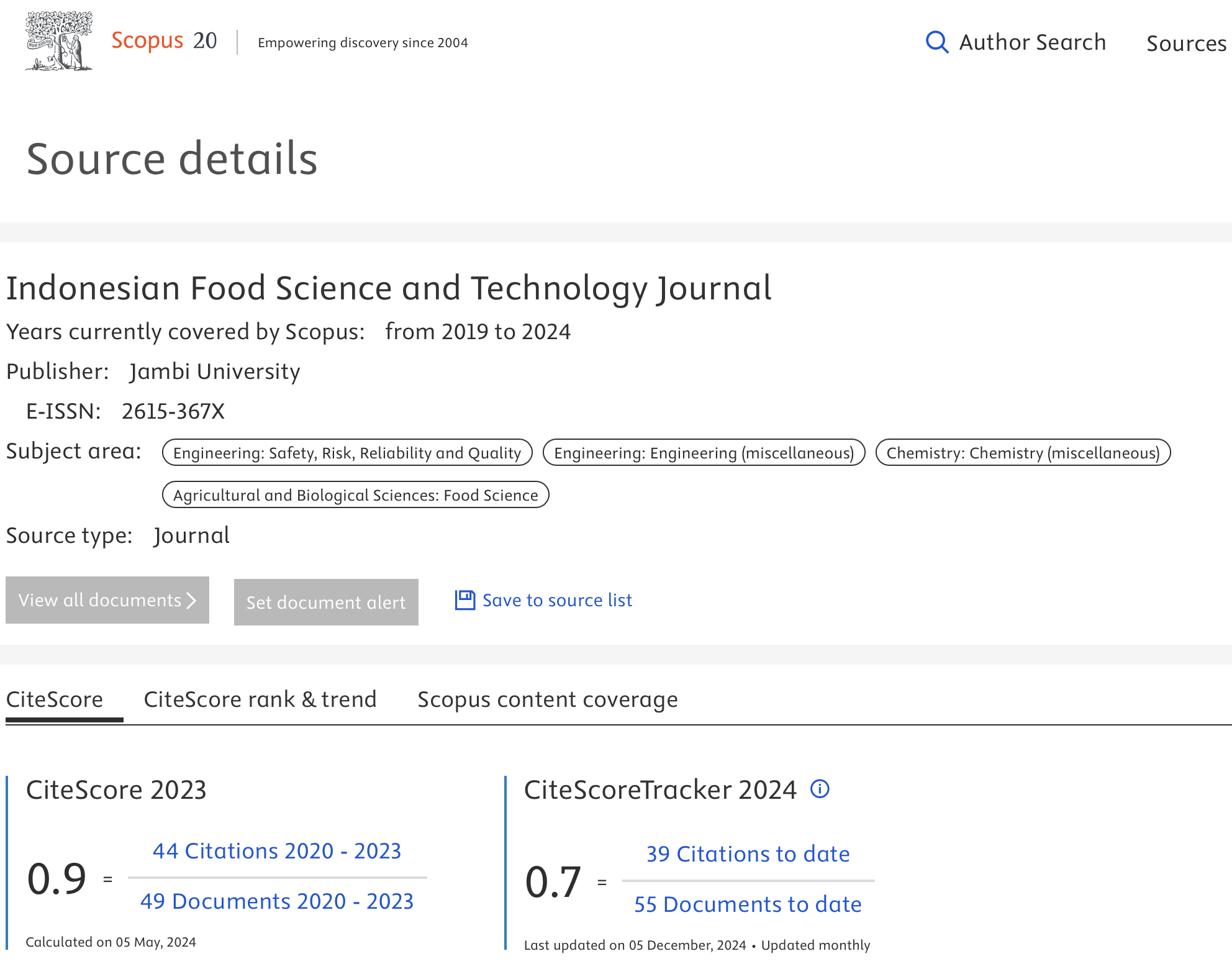

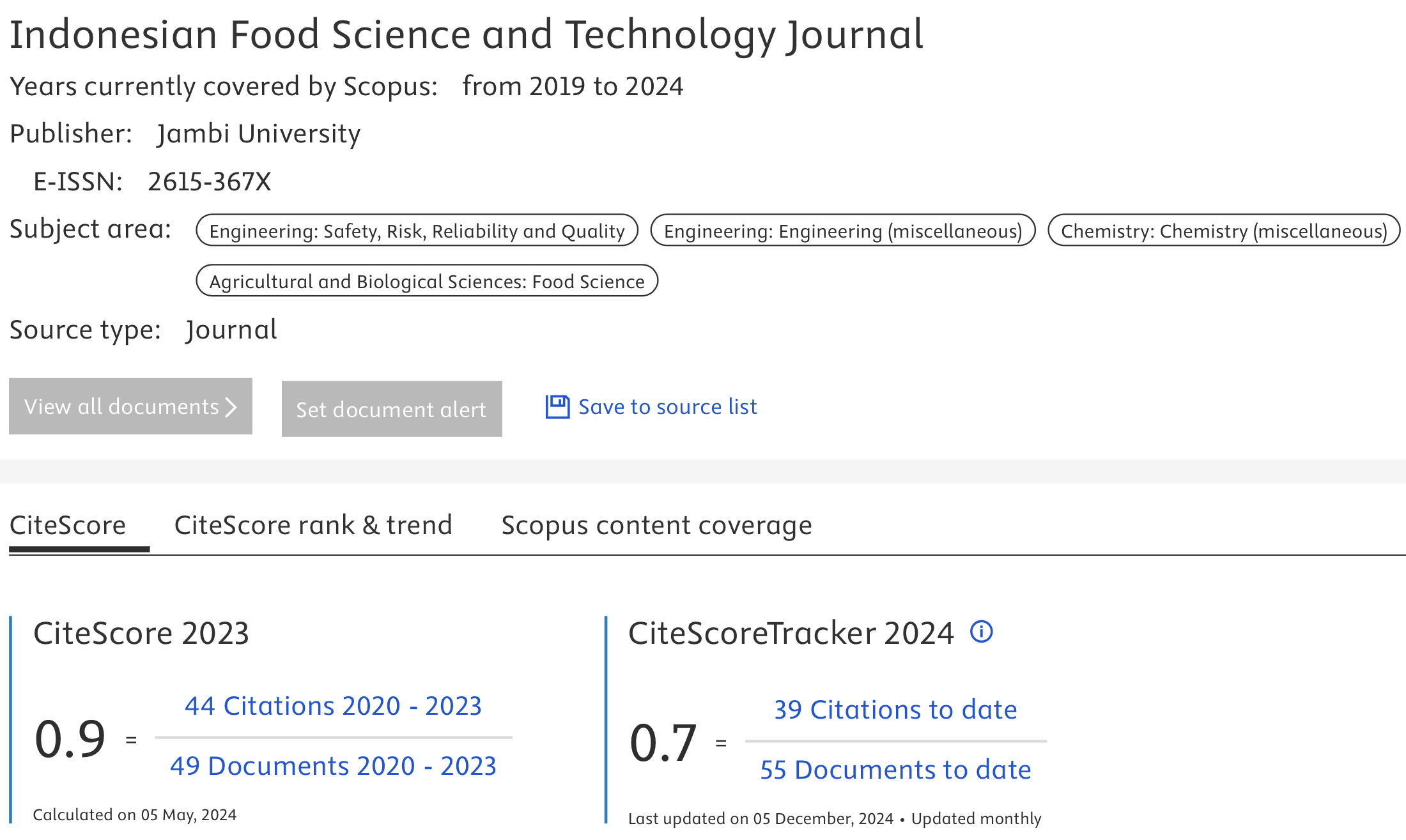

A Study On Physicochemical And Sensory Characteristics Of Eggless Yellow Cake

DOI:

https://doi.org/10.22437/ifstj.v2i1.6077Keywords:

egg; xanthan gum; eggless cakeAbstract

To evaluate the practicability of full substitution of eggs in production of a cake, different concentrations (0.5%, 1.0% and 1.5%) of xanthan gum were used. The results showed that substituting eggs with 0.5% xanthan gum inside a cake produced a harder cake and lower its moisture content, water activity and volume compared to control (1599.66 and 1945.69 g, 28.87 and 26.97%, 0.91 and 0.89, 523.33 and 425.00 cm3, respectively). The sensory evaluation result showed that the addition of 0.5% xanthan gum to an eggless cake received the highest acceptability among other eggless cakes. In conclusion, the addition of 0.5% xanthan gum produced the most promising substitute for eggs in cakes.

Downloads

References

[2] National Food Service Management Institute. (2009). Culinary techniques for healthy school meals (2nd ed.). University, MS: Author.

[3] Dhanapala, P., Silva, C. De, Doran, T., & Suphioglu, C. (2015). Cracking the egg : An insight into egg hypersensitivity. Molecular Immunology, 66(2), 375–383.

[4] Corrin, T., & Papadopoulos, A. (2017). Understanding the attitudes and perceptions of vegetarian and plant-based diets to shape future health promotion programs. Appetite, 109, 40–47.

[5] Arozarena, I., Bertholo, H., Empis, J., Bunger, A., & de Sousa, I. (2001). Study of the total replacement of egg by white lupine protein, emulsifiers and Xanthan gum in yellow cakes. European Food Research and Technology, 213(4–5), 312–316.

[6] Ghashghaei, T., Soudi, M.R., & Hoseinkhani, S. (2016). Optimization of xanthan gum production from grape juice concentrate using Plackett-Burman design and response surface methodology. Applied Food Biotechnology, 3 (1), 15–23.

[7] Niknezhad, S.V., Asadollahi, M.A., Zamani, A., Biria, D. (2016). Production of xanthan gum by free and immobilized cells of Xanthomonas campestris and Xanthomonas pelargonii. International Journal of Biological Macromolecules, 82 (751), 756.

[8] Lin, M., Hong, S., Yang, H., Yang, B., & Li, H. (2017b). Replacement of eggs with soybean protein isolates and polysaccharides to prepare yellow cakes suitable for vegetarians. Food Chemistry, 229, 663–673.

[9] Kohrs, D., Herald, T. J., Aramouni, F. M., & Abughoush, M. (2010). Evaluation of egg replacers in a yellow cake system. Emirates Journal of Food and Agriculture, 22(5), 340–352.

[10] Lin, M., Tay, S. H., Yang, H., Yang, B., & Li, H. (2017a). Development of eggless cakes suitable for lacto-vegetarians using isolated pea proteins. Food Hydrocolloids, 69, 440–449.

[11] AACC. (2000). Approved Methods of the American Association of Cereal Chemists (10th ed.). St. Paul, MN.

[12] Jeddou, K.B., Bouaziz, F., Zouari-Ellouzi, S., Chaari, F., Ellouz-Chaabouni, S., Ellouz-Ghorbel, R., & Nouri-Ellouz, O. (2017). Improvement of texture and sensory properties of cakes by addition of potato peel powder with high level of dietary fiber and protein. Food Chemistry, 217, 668-677.

[13] Hwan, J., Jung, H., Lee, H., Lim, E., Imm, J., & Joo, H. (2012). Physical and sensory characteristics of fibre-enriched sponge cakes made with Opuntia humifusa. LWT - Food Science and Technology, 47(2), 478–484.

[14] Mine, Y. (2008). Egg bioscience and biotechnology. Hoboken, New Jersey: John Wiley and Sons.

[15] Borneo, R., Aguirre, A., & León, A. E. (2010). Chia (Salvia hispanica L) gel can be used as egg or oil replacer in cake formulations. Journal of the American Dietetic Association, 110(6), 946–949.

[16] [16] Fernandes, S. S., & Salas-mellado, M. D. M. (2017). Addition of chia seed mucilage for reduction of fat content in bread and cakes. Food Chemistry, 227, 237–244.

[17] Janjarasskul, T., Tananuwong, K., & Kongpensook, V. (2016). Shelf life extension of sponge cake by active packaging as an alternative to direct addition of chemical preservatives. LWT - Food Science and Technology, 72, 166–174.

[18] Gòmez, M., Ronda, F., Caballerro, P.A., Blanco, C.A., & Rosell, C.M. (2007). Functionality of different hydrocolloids on the quality and shelf-life of yellow layer cakes. Food Hydrocolloids, 21, 167-173.

[19] Sahraiyan, B., Naghipoor, F., Najafi, M.B.H., Karimi, M., Khodaparast, M.H.H., & Davoodi, M.G. (2015). Production of eggless cake. Ferdowsi University of Mashhad. ResearchGate.net.

[20] Tan, M. C., Chin, N. L., Yusof, Y. A., Taip, F. S., & Abdullah, J. (2015). Improvement of Eggless Cake Structure Using Ultrasonically Treated Whey Protein. Food and Bioprocess Technology, 8(3), 605–614.

[21] Wilderjans, E., Pareyt, B., Goesaert, H., Brijs, K., & Delcour, J. A. (2008). The role of gluten in a pound cake system: A model approach based on gluten-starch blends. Food Chemistry, 110(4), 909–915.

Downloads

Published

Versions

- 2019-07-21 (1)

- 2019-07-21 (1)

How to Cite

Issue

Section

License

Copyright (c) 2018 Indonesian Food Science & Technology Journal

This work is licensed under a Creative Commons Attribution 4.0 International License.