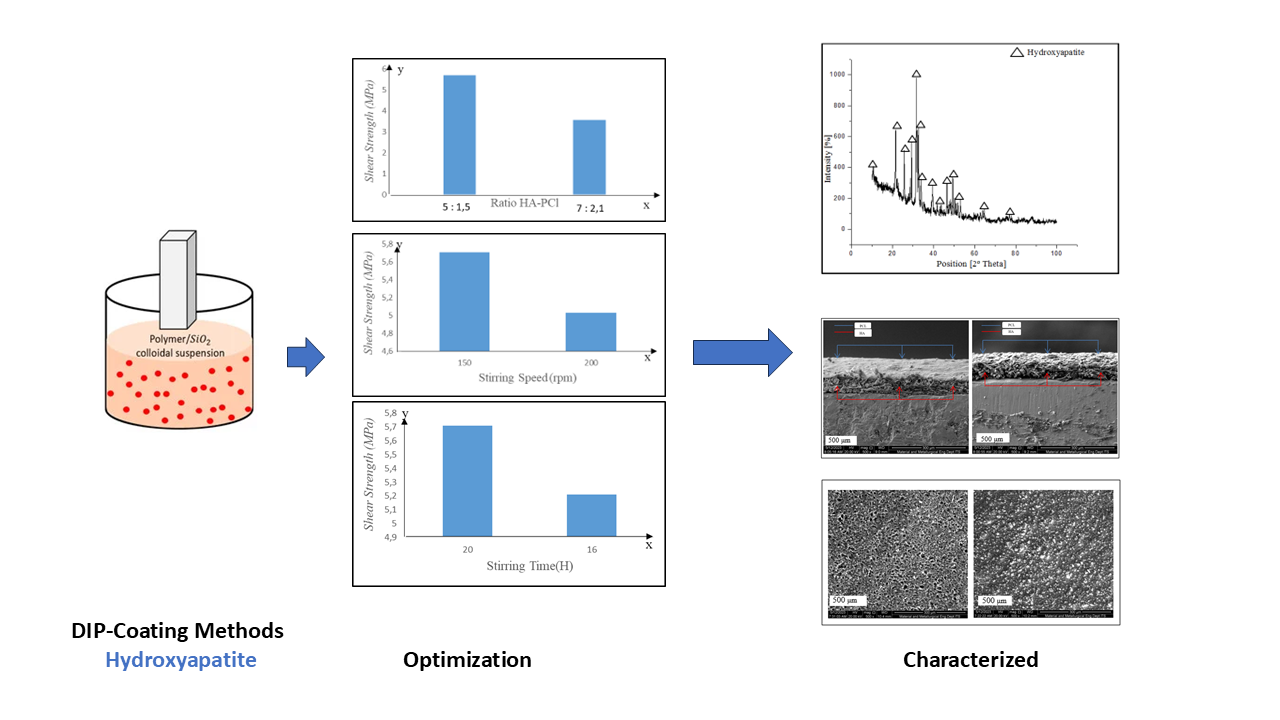

PELAPISAN HIDROKSIAPATIT- POLYCAPROLACTONE PADA PERMUKAAN STAINLESS STEEL 316L DENGAN METODE DIP COATING

Kata Kunci:

Empirical Model, Hydroxyapatite-Polycaprolactone, Stainless Steel 316LAbstrak

Stainless steel 316L is a metal that can be used for bone implants but exhibits low biocompatibility. The low biocompatibility can lead to inflammation, infection, or rejection within the body's tissue system. It is coated with hydroxyapatite-polycaprolactone to enhance the biocompatibility of stainless steel 316L. This study aims to examine the effects of stirring time, stirring speed, and the appropriate hydroxyapatite-polycaprolactone ratio on the shear strength of hydroxyapatite-polycaprolactone using the dip coating method and to determine the empirical model for the resulting shear strength of the hydroxyapatite-polycaprolactone layer. Hydroxyapatite and polycaprolactone were mixed using acetone and stirred at a speed of 150 rpm for 20 hours. Then, the stainless steel 316L substrate was immersed in the suspension and dried at 56°C for 1 hour. The process conditions optimization in this study employed a 2k modeling approach. The empirical shear strength model in this research is represented as y = -216.9 + 36.42A + 1.426B + 14.43C - 0.2345AB - 2.380AC - 0.08943BC + 0.01468AB*C, with an R2 value of 0.99. The variables with the most significant influence on shear strength, ranked from largest to smallest, are the HA-PCl ratio (A), followed by the two-way interaction between the HA-PCl ratio (A) and stirring speed (B), the three-way interaction between the HA-PCl ratio (A), stirring speed (B), and stirring time (C), followed by the two-way interaction between the HA-PCl ratio (A) and stirring time (C), stirring time (C), stirring speed (B), and the two-way interaction between stirring speed (B) and stirring time (C). The highest shear strength of the hydroxyapatite layer was achieved at a HA-PCl ratio of 5:1.5, stirring speed of 150 rpm, and stirring time of 20 hours, with a value of 5.71 MPa

Unduhan