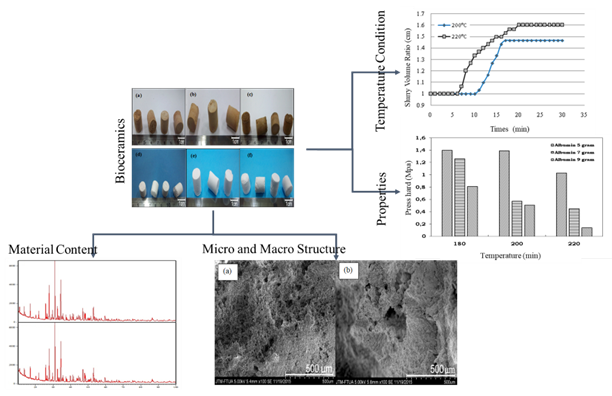

Porous Bioceramics use Albumin as a Pore-Forming Material

DOI:

https://doi.org/10.22437/chp.v7i1.8131Keywords:

compressive strength, albumin, porosity, tricalcium phosphateAbstract

Porous bioceramics have been used in biomedical field, especially for bone implant. To generate pores in bioceramics, pore creating substances are added into the process of making ceramic bodies. The purpose of this study is to make porous bioceramics with tri calcium phosphate (TCP) raw material using albumin with variation in the amount of albumin in the raw material and drying temperature on the physical and chemical properties of TCP. Raw material slurry was made by mixing 7 g of TCP, 2 g of starch and 1.5 g of Darvan 821A with 5 g, 7 g and 9 g of albumin in a beaker glass while stirring at a rate of 150 rpm for 3 hours. The slurry was poured into a mold and heated in an oven at 180°C, 200°C and 220°C for 1 hour. Subsequently the sample was burned at 600˚C for 1 hour, following with sintering at 1.100°C for 2 hours. Bioceramic porosity is greater by increasing the amount of albumin and drying temperature, while the compressive strength decreases. Obtained TCP porosity is in the ranges of 68% -78% and compressive strength 0.14-1.4 MPa.

Downloads

References

Sopyan, I., Mel, M., Ramesh, S., & Khalid, K. A. (2007). Porous hydroxyapatite for artificial bone applications. Science and Technology of Advanced Materials, 8(1–2), 116–123. https://doi.org/10.1016/j.stam.2006.11.017

Uchida, A., Nade, S., McCartney, E., & Ching, W. (1984). The use of ceramics for bone replacement. A comparative study of three different porous ceramics. The Journal of Bone and Joint Surgery. British Volume, 66-B(2), 269–275. https://doi.org/10.1302/0301-620X.66B2.6323483

Otsuki, B., Takemoto, M., Fujibayashi, S., Neo, M., Kokubo, T., & Nakamura, T. (2006). Pore throat size and connectivity determine bone and tissue ingrowth into porous implants: Three-dimensional micro-CT based structural analyses of porous bioactive titanium implants. Biomaterials, 27(35), 5892–5900. https://doi.org/10.1016/j.biomaterials.2006.08.013

Nettleship, I. (1996). Applications of Porous Ceramics. Key Engineering Materials, 122–124, 305–324. https://doi.org/10.4028/www.scientific.net/KEM.122-124.305

Sopyan, I., Fadli, A., & Mel, M. (2012). Porous alumina–hydroxyapatite composites through protein foaming–consolidation method. Journal of the Mechanical Behavior of Biomedical Materials, 8, 86–98. https://doi.org/10.1016/j.jmbbm.2011.10.012

Xia, F., Cui, S., & Pu, X. (2022). Performance study of foam ceramics prepared by direct foaming method using red mud and K-feldspar washed waste. Ceramics International, 48(4), 5197–5203. https://doi.org/10.1016/j.ceramint.2021.11.059

Kozhukhova, N., Kozhukhova, M., Teslya, A., & Nikulin, I. (2022). The Effect of Different Modifying Methods on Physical, Mechanical and Thermal Performance of Cellular Geopolymers as Thermal Insulation Materials for Building Structures. Buildings, 12(2), 241. https://doi.org/10.3390/buildings12020241

Fadli, A., Rasyid, A., & Firmansyah, R. (2014). Effect of Sintering Temperature Rate on Physical Properties of Porous Tricalcium Phosphate (TCP) Ceramics. ASEAN COSAT , 427–432.

Yatim, N. H., & Rahman, H. A. (2020). Influences of Starch on Ceramic-Foam Fabrication: A Short Review. IOP Conference Series: Materials Science and Engineering, 824(1), 012001. https://doi.org/10.1088/1757-899X/824/1/012001

Sanusi, A. Z., Jibia, Z. S., Garba, M. G., Salisu, U. S., & Gaddafi, S. (2020). Functional Properties of Powdered and Fresh Egg Albumin and Yolk Determination. FUDMA Journal of Sciences, 4(3), 263–266. https://doi.org/10.33003/fjs-2020-0403-390

FoodChem International Coorporation. (2015, November 8). Material Safety Data Sheet Tricalcium Phosphate MSDS. http://www.foodchemadditivies.com

Fadli, A., & Sopyan, I. (2011). Porous ceramics with controllable properties prepared by protein foaming-consolidation method. Journal of Porous Materials, 18(2), 195–203. https://doi.org/10.1007/s10934-010-9370-8

Fadli, A., & Sopyan, I. (2009). Preparation of porous alumina for biomedical applications through protein foaming–consolidation method. Materials Research Innovations, 13(3), 327–329. https://doi.org/10.1179/143307509X440668

Sari, M., Hening, P., Chotimah, Ana, I. D., & Yusuf, Y. (2021). Bioceramic hydroxyapatite-based scaffold with a porous structure using honeycomb as a natural polymeric Porogen for bone tissue engineering. Biomaterials Research, 25(1), 2. https://doi.org/10.1186/s40824-021-00203-z

Chen, Y., Wang, N., Ola, O., Xia, Y., & Zhu, Y. (2021). Porous ceramics: Light in weight but heavy in energy and environment technologies. Materials Science and Engineering: R: Reports, 143, 100589. https://doi.org/10.1016/j.mser.2020.100589

Fadli, A., & Komalasari. (2013). Metode Pembuatan Komposit Berpori Menggunakan Cara Protein Foaming-Starch Consolidation (Patent No. P00201304608).

Gibson, L. J., & Ashby, M. F. (1997). Cellular Solids Structure and Properties. Cambridge University Press. https://doi.org/10.1017/CBO9781139878326

Fadli, A., & Sopyan, I. (2010). Porous Alumina through Protein Foaming-Consolidation Method: Effect of Stirring Time and Drying Temperature on the Physical Properties. Advanced Materials Research, 93–94, 397–400. https://doi.org/10.4028/www.scientific.net/AMR.93-94.397

Su, M., Shih, K., & Chen, D. (2021). Advances in Cadmium Detoxification/Stabilization by Sintering with Ceramic Matrices (pp. 299–323). https://doi.org/10.1007/978-3-030-54626-7_7